Overview

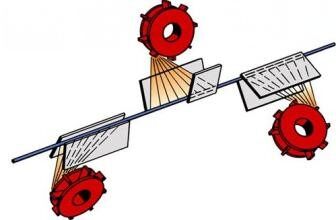

A new type of equipment independently developed by our company through wire through shot blasting cleaning machine. It is improved on the basis of our company's extensive domestic research and based on the urgent requirements of users.

Wire-through shot blasting cleaning machine has the following advantages:

1. The fifth-generation cantilever centrifugal shot blaster is used in the international market with large shot blasting volume and high pitching speed. The belt type is used between the shot blaster and the drive motor, which can greatly reduce the footprint of the shot blaster, thereby effectively reducing the size of the equipment, significantly improving the cleaning efficiency and achieving satisfactory cleaning quality.

2. Adopting a popular pit-free structure form not only saves the construction cost and time of pit foundations, but also solves the problem of rust and agglomeration of ball sand in the elevator caused by water storage in the pits by southern users.

3. The cleaning room is protected by rolled Mn13 steel plates, which greatly improves its service life, and is beautiful in appearance and is easy to replace. It is the most popular way to protect the cleaning room.

Use

This type of wire shot blasting machine is suitable for surface cleaning or strengthening treatment in chemical, motor, wire drawing and other industries. It is especially suitable for surface cleaning and shot blasting reinforcement of the disk element wire to remove a small amount of oxide scale on the surface of the workpiece.

Shot blasting cleaning has the following advantages compared with other cleaning techniques:

Wire shot blasting machines improve the fatigue resistance of mechanical products and metal components, eliminate stress concentration, extend their service life, optimize the surface process status of the workpiece, greatly improve cleaning efficiency, reduce labor intensity of cleaning work, and reduce environmental pollution.

Technical parameters and requirements of wire shot blasting machine

| 1 | Cleaning workpiece range | high-speed tool steel |

| Wire diameter | φ4-φ16mm | |

| Feeding speed | ≤60m/min (speed regulation is determined by the wire drawing machine or wire collector) | |

| 2 | Shot blaster power | 4×22KW (frequency conversion speed regulation) |

| 3 | Lift power | 4KW |

| 4 | Wind speed of separator separation zone | 4-5m/s |

| 5 | Screw conveyor power | 3KW |

| 6 | The particle size of the projectile | φ0.2-φ0.3mm |

| 7 | Pulse system | QM pneumatic gate |

| 8 | The air volume of dust removal system | 5000m3/h |

| 9 | Pre-modulation system (electric feed) power | 3kw |

| 10 | The total machine ratio | 103.5KW |