Introduction to the Functions of Telescopic Spray booths

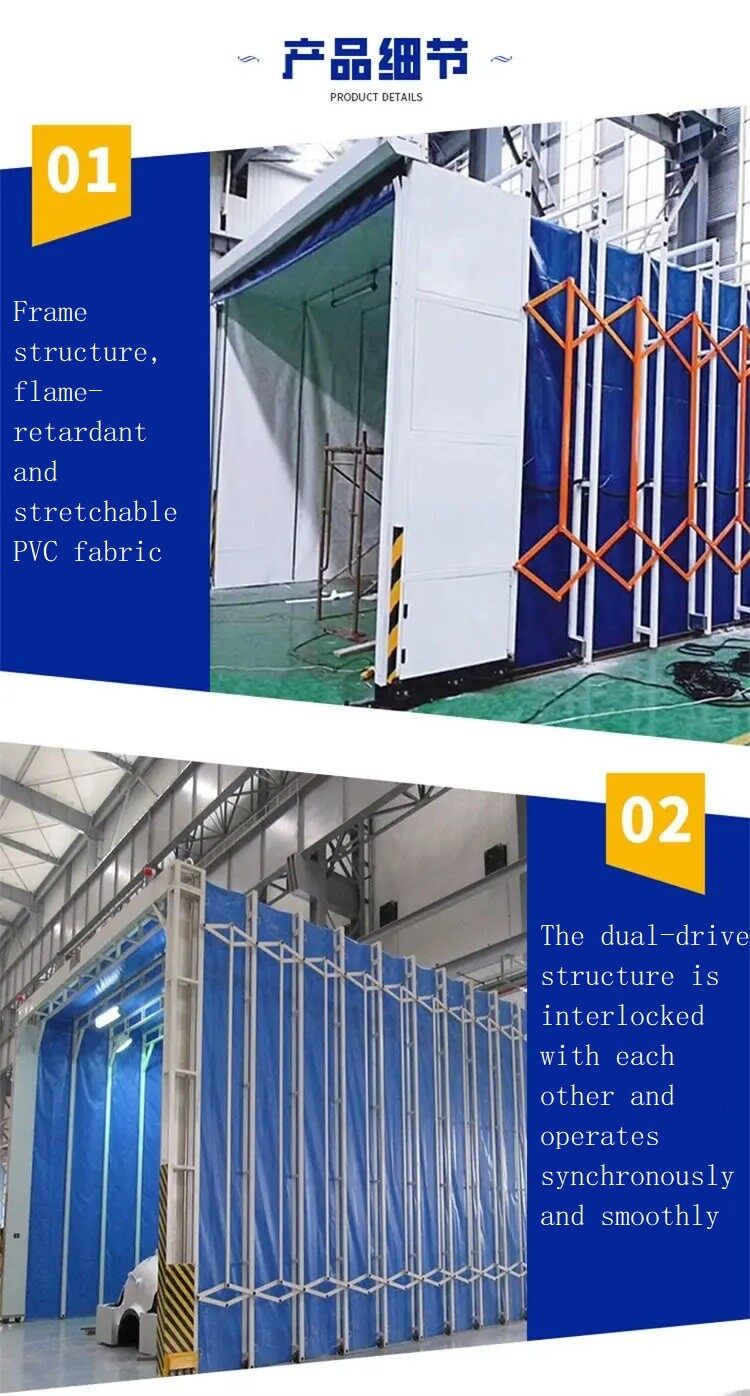

The retractable spray booth, also known as the mobile spray booth, retractable canopy or dust-free spray booth, is an environmentally friendly coating equipment that can be freely extended, unfolded and contracted like an accordion through electric control. Essentially, it is a movable "room" that provides a closed working space, offering a controllable environment for processes such as painting, grinding, repairing and drying of workpieces, especially large and immovable ones.

Introduction to the core functions of the telescopic spray booth

Provide a closed spray painting environment

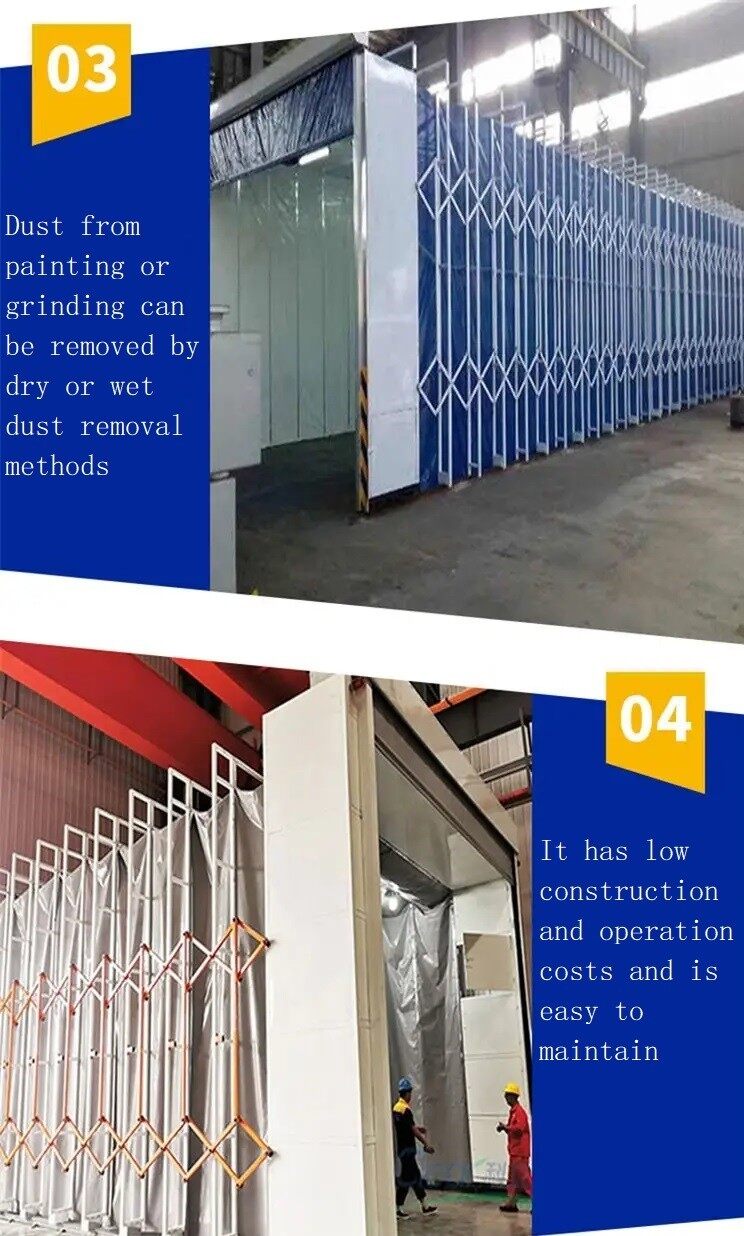

Dust-proof: After unfolding, it forms a completely enclosed space, which can effectively isolate dust, debris and flying insects in the outside air, ensuring the cleanliness of the painted surface and improving the quality of spraying.

Environmental protection: Prevent paint mist and volatile organic compounds (VOCs) from spreading to external workshops, protecting the surrounding environment and the health of workers.

Paint mist treatment and waste gas collection

It is usually equipped with top or side filtration systems (such as top cotton/air inlet filter cotton) to filter the air entering the room and ensure the supply air is clean.

At the rear end of the room, there are high-efficiency paint mist filtration devices (such as floor cotton, labyrinth paper boxes, dry or wet filtration systems) installed, which can capture and adsorb oversprayed paint mist particles.

It can be connected to waste gas treatment equipment (such as activated carbon adsorption, photo-oxygen catalysis, catalytic combustion devices) to conduct secondary purification of the treated waste gas, meeting the requirements of environmental protection emissions.

Forced ventilation and air flow organization

The built-in ventilation system (exhaust fan) forms a directional airflow from one side to the other.

This negative pressure airflow can quickly transform the floating paint mist into a directional airflow from one side to the other and discharge it through the tail exhaust port, ensuring that the paint mist does not remain in the operator's breathing zone and improving the working environment.

Lighting system

The top of the room is equipped with high-brightness and explosion-proof LED lighting fixtures, providing sufficient and shadow-free illumination for the spray painting operation, ensuring no blind spots in the spraying process and accurate color judgment.

Flexible spatial transformation

Core function: Controlled by buttons, the house can move smoothly on the track and extend and retract as needed. When working, it spreads out to cover the workpiece. After the work is completed, it retracts and closes to release the working area.

The main advantages of the telescopic spray booth:

The telescopic spray booth, due to its unique design, has many significant advantages over the traditional fixed spray booth:

Great spatial flexibility and space-saving

One room for multiple uses: The greatest advantage. When not in use, the spray booth can be retracted, and the original site can be immediately used for other operations (such as grinding, assembly, parking equipment, etc.), which is particularly suitable for small and medium-sized enterprises, maintenance workshops and 4S stores with limited space.

No dedicated space required: It solves the problem that fixed spray booths permanently occupy a large area of space.

Low investment cost, economical and practical

Low construction cost: Compared with building a fixed brick-concrete or steel structure spray booth, the manufacturing cost and installation cost of a telescopic spray booth are lower.

Low infrastructure requirements: No complex civil engineering works are needed. Only a flat site and pre-laid tracks are required, and the construction period is extremely short.

It has a wide range of applications, especially suitable for large workpieces

It can easily accommodate and cover large, heavy or immovable objects, such as: large mechanical equipment, engineering vehicles, buses, yachts, containers, molds, etc. The workpiece remains fixed and is covered by a "room", solving the problem of large workpieces entering and leaving the fixed room.

It is easy to operate and highly efficient

Electrically controlled expansion and contraction, the operation is simple and fast, usually only taking 1-2 minutes to complete the conversion, which improves the turnover and utilization efficiency of the workstations.

Environmental protection compliance

It can integrate a complete paint mist and waste gas treatment system, helping enterprises meet increasingly strict environmental protection regulations and achieve standard emissions.

Mobility and scalability

If the factory building needs to be relocated in the future, the fixed spray booth cannot be moved, while the telescopic spray booth can be disassembled and reinstalled at a new site, avoiding investment losses.

Theoretically, its coverage can be increased by extending the track, which has a certain degree of scalability.

The applicable scenarios of the telescopic spray booth

Automobile repair and 4S stores: Used for painting complete vehicles or large sheet metal parts.

Large-scale equipment manufacturing and maintenance: such as excavators, cranes, agricultural machinery, aircraft components, etc.

Ships and rail transit: Repair and painting of yacht and train carriage components.

Furniture and building materials industry: large custom furniture, doors and Windows, etc.

Any place where space is tight and intermittent spray painting operations are required.

Precautions for telescopic spray booths

Sealing performance: Compared with top-grade fixed rooms, the sealing performance of its telescopic structure may be slightly inferior, but it is completely sufficient for most industrial applications.

Durability: The quality of the shed material (usually high-strength PVC-coated fabric or flame-retardant and wear-resistant fabric) and the frame structure determine its service life.

Safety performance: It is necessary to be equipped with safety devices such as fire protection and leakage protection, especially the lighting and fans must be explosion-proof.

In conclusion, the retractable spray booth, with its core concept of "unfolding when in use and retracting when idle", perfectly resolves the contradiction between space utilization and professional spray painting demands. It is an environmentally friendly coating solution that is highly cost-effective and practical.